|

Jinhong Plastic Hardware Mould Fittings Co.,ltd

|

Jinhong Plastic mold components INTERNAL LATCH LOCK 1

| Price: | 666.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

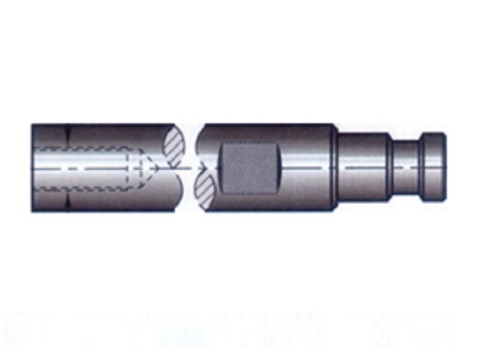

Jinhong Mould Fittings INTERNAL LATCH LOCK DKL-1

Product features:

1.The product is installed inside the mould, avoiding conflict with the external parts of the mould and the waterways;

2.The product has different functions according to the The product installation methods, and has the functions of internal latch lock and secondary ejection device, being widely applicable.

Installation and use instructions:

1.Install the inner bushing, fix the inner bushing on the fixed mould in direction vertical to the mould joint by using a hexagonal socket head cap screw, and accurately calculate the first mould opening stroke before installation;

2.Install the outer bushing, fix the outer bushing on the runner plate in direction vertical to the mould joint through a screw cap, and make the outer bushing concentric with the inner bushing;

3.Install the central insertion rod after installing the outer bushing and the inner bushing symmetrically on the mould and determining that they are correctly installed and run normally;

4.Conduct the fit function test to check whether the movement of all parts for the reset mechanism is smooth, and the stroke is consistent;

5.The internal latch locks are precision devices, which should be positioned in kind and installed symmetrically;

6.It is recommended that 4 internal latch locks should be used for each mould;

7.There are three diameters: 28MM, 34MM and 45MM. Select according to the mould size. There are two stroke ranges and central rod lengths respectively for three models;

8.If the mould is required to be repaired, remove the internal latch locks and then conduct the subsequent operation;